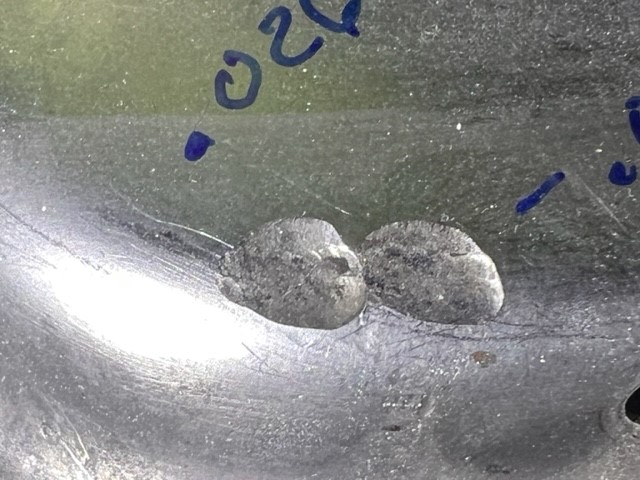

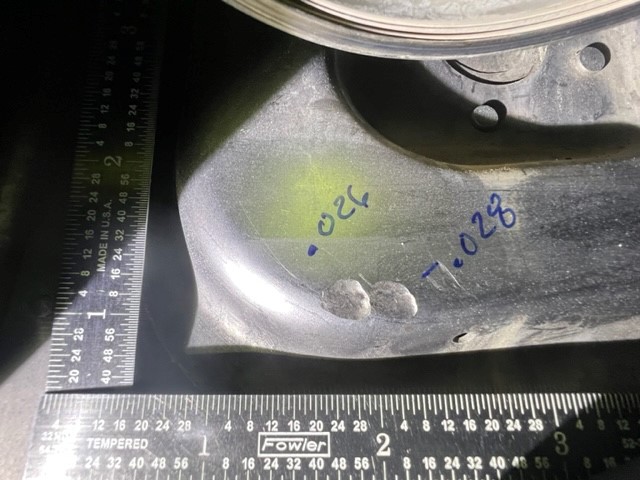

During engine R&R or during a 120/240-month inspections, West Star Aviation has been discovering chafing of the fixed cowl on Global aircraft from a bleed air clamp. This chafing has been observed roughly 15 to 18 times over the past two years.

The issue requires a Technical Variance, in which Rolls-Royce will either call out a repeat inspection of the area. Technical Variance normally requires a reoccurring inspection of the chaffed area every 50 Flight hours up to 200 flight hours. At 200 flight hours a blend or weld repair will be required. If weld repair is required, the engine and fixed cowl must be removed in order to complete the weld.

In some instances, Rolls-Royce may require an immediate repair if the chafe is too deep. The repair for this issue is a titanium weld repair, with the process taking about 7 to 9 working days.

For more detailed information, please contact one of the West Star Aviation Global Specialists listed below.

Robert Peyman

Technical Sales Manager

Challenger & Global

(ALN)

Tel 618.258.8090

rpeyman@wsa.aero

George Laiten

Director of Bombardier Product

Development

Cell 618.798.1173

glaiten@wsa.aero

Jeff Olson

Challenger Program Manager

(GJT)

Tel 970.248.5254

jolson@wsa.aero

Steve Smith

Challenger/Global Program Manager

(CHA)

Cell 423.356.0325

stsmith@wsa.aero

Randy Miller

Technical Sales Manager Challenger & Global

(GJT)

Tel 970.248.5270

rmiller@wsa.aero

Jeff Messmer

Technical Sales Manager

(PCD)

Cell 314.607.4069

jmessmer@wsa.aero

Larry Marler

Technical Sales Manager

(CHA)

Tel 423.598.1578

lmarler@wsa.aero

- Posted in App, Global Express Tips, News

- No Comments