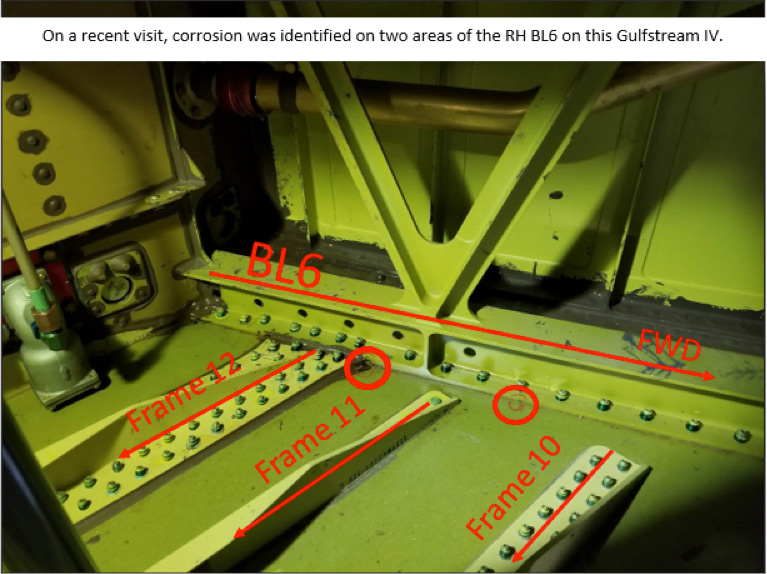

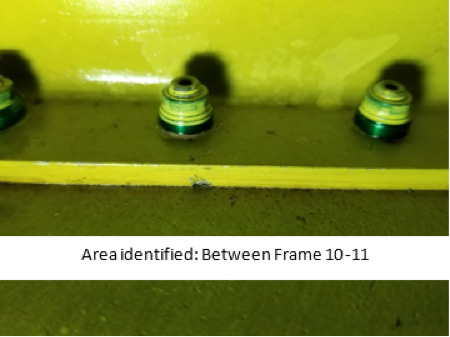

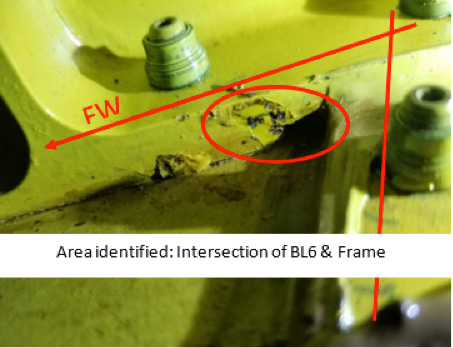

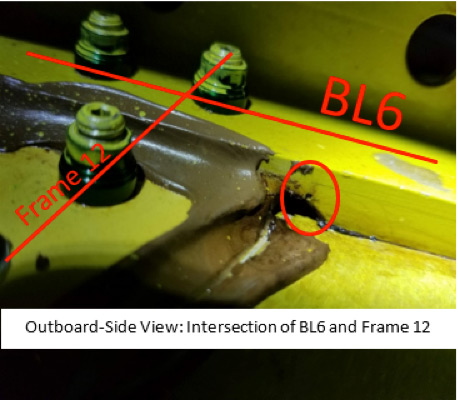

We all know airframe corrosion is a serious issue. Depending on the location, identifying the presence of corrosion and repairing it can get complicated. Although not easy to spot, corrosion on BL6 must be treated and repaired per Gulfstream Engineering. This type of corrosion is most commonly found during a 24-month inspection while the inboard fuel panels are removed, and the internal wing area is examined. Depending on the severity of the corrosion, treatment can range from blending to complete replacement of BL6. If this corrosion removal is blended beyond limits, then a wing demate is necessary to access and repair the problem.

Regular inspections are key to catching the problem early and devising a plan to repair the damage to get your aircraft back in the air safely. West Star Aviation’s specialized Gulfstream Team has the experience and know-how to properly identify, then demate the wing and repair this corrosion on the GIV.

IDENTIFICATION

Accessing the BL6 Area For Repair: WING DEMATE

LET’S TAKE A CLOSER LOOK

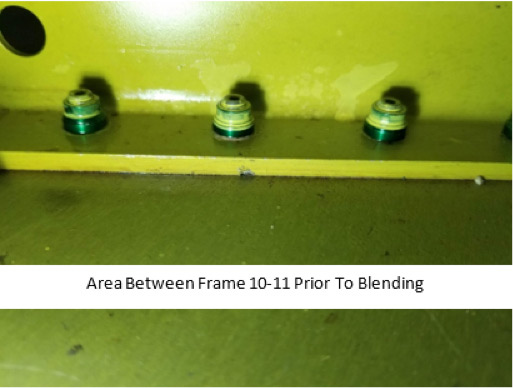

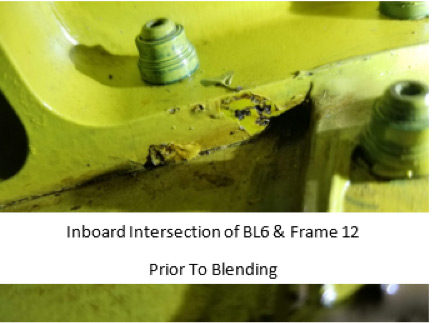

Corrective Action Taken:

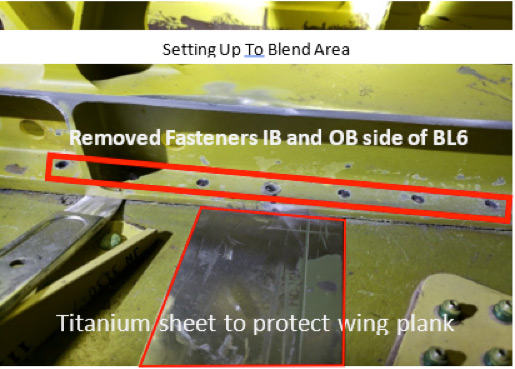

- In each area of corrosion, prior to subsequent operations, remove adjacent fasteners that attach the rib to the plank. Afterwards, we recommend that you carefully wedge thin stainless-steel sheet or other material between rib and plank to protect the plank.

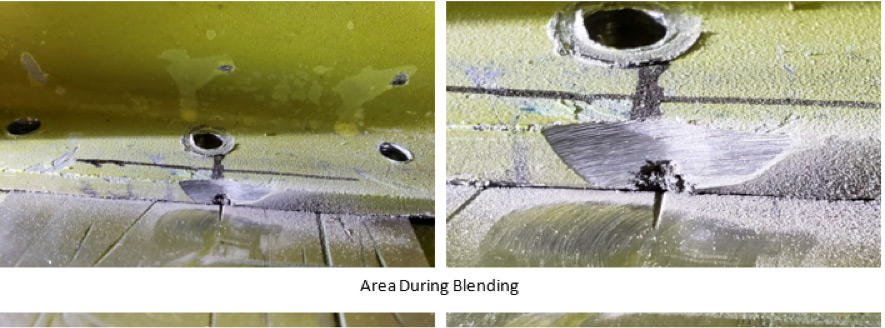

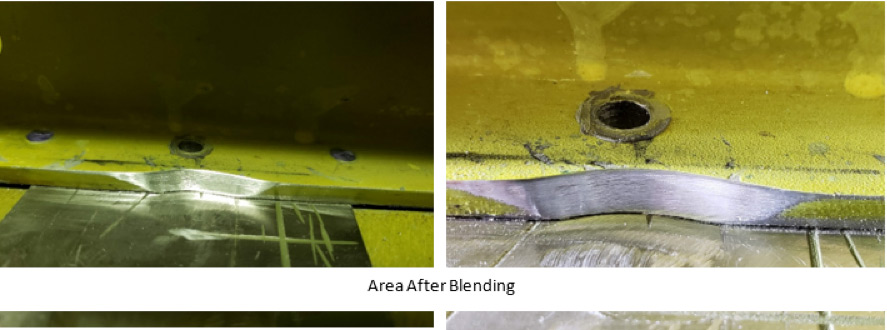

- Blend or machine out the minimum amount of material to remove corrosion, maintain a 10:1 width to depth ratio and 63Ra (micro-inch) or smoother surface finish. If more than a topical blending is required, machine a dog bite or scallop shaped cutout from rib, depth into rib flange not to exceed 0.125″. NOTE: Be cautious and mindful to remove only the minimum amount of material required.

THE REPAIR

NDI Found No Remaining Corrosion. Final Polish, Alodine & Paint To Follow.

Further Action Required. Corrosion Still Present After Initial 0.125” Removal Of Material. Measurements & Photos Submitted To Engineering.

- Posted in Gulfstream Tips, News

- No Comments